Demand planning with supply chains to create certainty and productivity

Demand planning is a simple but effective approach which drives productivity and enables confidence in delivery performance. Read the latest insights as part of our Realising the extraordinary series focusing on how supply chains and client organisations can achieve greater certainty in major projects.

By Principal Consultant Stephen Gallagher and Project Director Elaine Hobbs

In many ways, demand planning can be very simple – it’s about working with the people and organisations that you rely upon and work with, and understanding the critical deliverables, resources, materials and other factors which will enable you to achieve objectives. When done well, demand planning is a highly-effective technique that enables client organisations to operate as one with their supply chain.

39 percent of respondents identified demand planning as critical for major project success, in a poll conducted in March 2021.

In recent years, we have seen a growing trend for the infrastructure sector to turn to other industries, such as high tech, manufacturing and retail, to look at what informs successful supply chain management. In the retail sector, supply chain relationships are formed with the acknowledgement that due to rapidly changing customer demands, there is a need for flexibility and adaptability in processes. We see client organisations build trusted relationships with their supply chains, which are then mutually underpinned by:

- Joint business plans focused on outcomes, rather than quantities or contractual agreements

- Shared data to predict the perfect balance between supply and demand

- Acknowledgement of each other’s strengths and focus

- A clear and consistent understanding of critical programme requirements

- Clear lines of communication

In the infrastructure sector, there has been a shift towards these more strategic partnerships which support better demand planning and we are seeing real evidence that this approach works. An example of this is Dragages and its design and build of a complex tower in Singapore. Through a series of collaborative planning workshops, the complex programme was broken down into smaller, more manageable pieces of work and the optimum sequence for delivery defined.

Productivity and supply chain relationships

Demand planning also identifies areas where waste can be driven out of programmes so that a leaner, more agile organisation and delivery can be achieved. At its most simplistic level, productivity is the total value of construction (GDP) divided by the total number of hours (hrs) worked – the time spent by workers performing their tasks. With demand planning, productivity can be increased as, for example, workers are not waiting for materials to arrive or undertaking tasks or sequencing work in a way which creates waste.

Impact on productivity from COVID-19

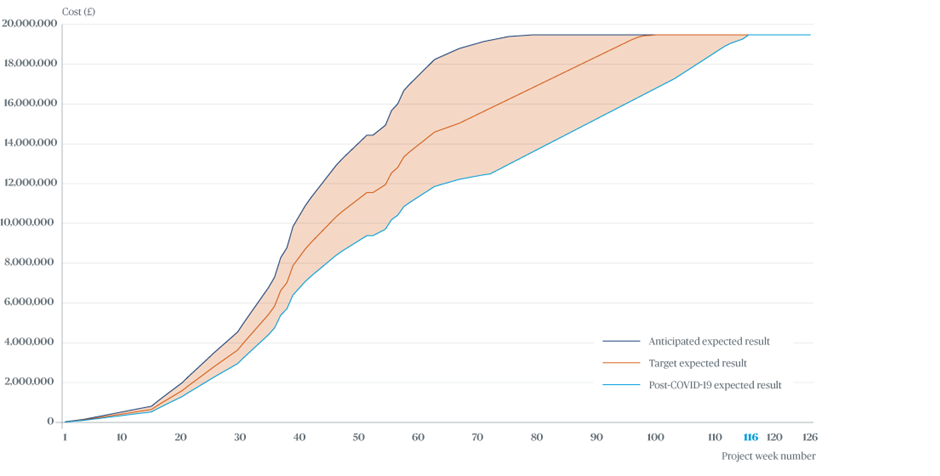

Our analysis in 2020 demonstrated that typically there is a 20 percent loss in productivity on projects, predominantly due to an inadequate supply of skills and resources, design information delays/inaccuracies and poor delivery planning. When faced with the COVID-19 crisis, up to a further 18 percent productivity loss was encountered in a typical medium-sized commercial real estate project (£20m).

While there are several factors contributing to these results, creating an efficient collaborative supply chain can dramatically improve output rates and create delivery reliability and certainty throughout all construction phases. Organisations which had robust demand planning in place were able to adapt more quickly to delays as teams could more easily adjust.

Four steps to effectively demand plan

The case for demand planning is clear, but organisations still do not implement it as a standard on major projects. To overcome this, the following four step process provides a framework for adopting demand planning:

1. Understand the critical path

Too often there isn’t a clear understanding of the complexity or critical path by all suppliers – contractors, systems providers, operators, designers and the client organisation. All stakeholders must have a realistic, honest understanding of the critical path and be able to continually access it, understand it and, if it changes, recognise that needs must be re-established. This approach enables more accurate demand planning, greater productivity and acts as an early warning system for potential disruptions.

2. Break down the programme into packages of activity

Once the critical path is clear, client organisations must break down the programme into daily packages of activity. This enables every supplier to understand what is required in each package – and how many resources or materials will be needed daily. By starting at the end of the programme and working back week by week, then day by day, much more accurate activity planning can be achieved. This granular planning can then be rolled up into other reporting or planning cycles.

Many organisations do not do this at a daily level and the most common sign that the package breakdown has not been appropriately done is the frequent changing of milestones. When this occurs, there is often a delay or limited availability in materials or resources which means that the right breakdown has not been developed in advance or the supply chain has not been engaged as part of this stage.

3. Work with all supply chain partners to deliver packages of activity

Once packages have been identified and suppliers engaged, delivery can commence more effectively and efficiently, as every supply chain team know what they need to do and how many resources they need every day. The supply chain team delivering the requirements will be more knowledgeable and be able to develop accurate resource requirement plans to determine their needs. They will also be able to better implement associated processes like onboarding of specialist skillsets or secure materials at the best rates.

Above all, supply chain partners and the client organisation must adhere to the plan, understand it and there must be assurance processes in place to ensure that this is happening. Assurance should not be a combative approach but instead, supply chains partners should be encouraged to identify over or under usage and re-balance resources to create efficiencies. It’s the client organisation’s responsibility to own the plan and be accountable for delivery, but they must also work collaboratively with suppliers in doing this.

4. Review plans daily to drive productivity and identify issues

By reviewing against daily plans, there are very quick and effective ways to identify any bottlenecks or supply challenges and actions required. Too often organisations only monitor demand plans weekly or monthly which results in the problem snowballing and programme-level implications arising. By breaking the delivery programme down, potential problems and opportunities can be identified and tracked, and remedial measures quickly put in place.

Combined, this granular daily delivery and demand monitoring will ultimately reduce time and cost. For maintenance and operations, the same approach can be adopted where data drives demand and a collaborative approach is adopted to achieve the outcomes required.

Behaviours and a scalable approach

Exceptional results are only sustained by working closely across the entire supply chain and client team to embed exceptional practices – both processes and behaviours. At its core, the right behaviours support successful demand planning.

Behavioural change is driven by business leaders and the client organisation. However, leadership teams – within supplier and client organisations – must understand how large the opportunity is to optimise performance and the importance that daily and programme-wide demand planning enables. They must enable it through:

- A compelling vision and sense of urgency – Communicating clearly how and why demand planning or a new approach is needed.

- Living values – The entire leadership team must be the first to exhibit the behaviours and practices needed. At a practical level, this means walking sites and identifying non-value adding activities and understanding on-site challenges.

- Identify a pilot project to trial practices and build knowledge.

- Communicate results and plan for expansion – To achieve scalable improvements, the principles proven in the pilot project must be captured and a business-wide rollout plan introduced.

Demand planning is a simple but effective approach which drives productivity and enables confidence in delivery performance. It can simply and effectively be applied in major projects and programmes and with supporting processes, behaviours and collaboration, boosts certainty and success.